When it comes to managing a business, monitoring key metrics is crucial to understanding how well your operations are performing. One area that requires close attention is purchase order reports. By tracking key metrics of purchase order reports, businesses can identify areas for improvement, streamline operations, and ultimately save money.

Understanding the Importance of Purchase Order Reports

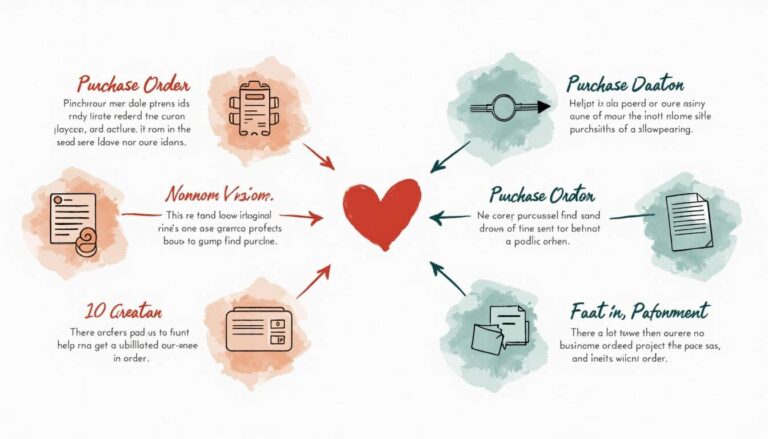

Purchase order reports are comprehensive records of all orders placed by a business with its vendors. These reports contain essential information such as order numbers, quantities, prices, and shipping details. Ultimately, purchase order reports provide businesses with critical insights into their procurement processes and supply chain management.

However, purchase order reports are more than just a record of business transactions. They play a vital role in ensuring that businesses run smoothly and efficiently. By tracking purchase orders, businesses can keep track of their inventory levels and ensure that they have enough stock to meet customer demand. This is especially important for businesses that operate in industries where demand can fluctuate rapidly, such as retail or manufacturing.

The Role of Purchase Order Reports in Business Operations

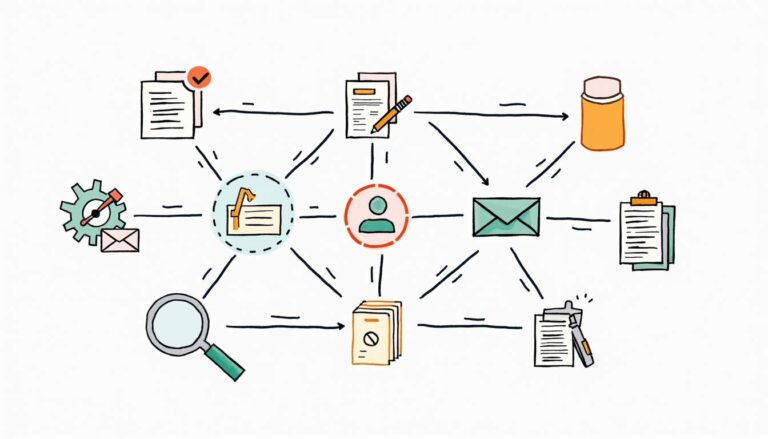

Purchase order reports are essential in modern businesses. They ensure that orders are accurately processed, deliveries are timely, and vendors are held accountable for errors. Simply put, these reports help businesses stay organized and efficient. By consistently tracking purchase order reports, businesses can identify trends in their purchasing habits, which can help them optimize their procurement processes for cost savings.

Moreover, purchase order reports can help businesses to maintain accurate financial records. By tracking all expenses related to purchases, businesses can accurately calculate their costs of goods sold and determine their profitability. This information is essential for making informed business decisions, such as whether to increase prices or cut costs.

Benefits of Regularly Analyzing Purchase Order Reports

Tracking purchase order reports can provide businesses with a broad range of benefits. One of the most significant advantages is that analyzing these reports helps to identify inefficiencies in the procurement process. By identifying common errors and areas of improvement, organizations can streamline these processes, reduce costs, and increase profitability. Additionally, regularly reviewing purchase order reports helps businesses build positive relationships with vendors and ensures that they consistently receive high-quality goods and services.

Another benefit of regularly analyzing purchase order reports is that it can help businesses to identify potential fraud or other irregularities. By reviewing the reports for unusual patterns, businesses can catch fraudulent activity early and take steps to prevent it from happening in the future.

Overall, purchase order reports are an essential tool for businesses of all sizes. By tracking and analyzing these reports, businesses can improve their procurement processes, maintain accurate financial records, and ensure that they consistently receive high-quality goods and services from their vendors.

Metric 1: Order Accuracy

The Impact of Order Accuracy on Business Efficiency

Accuracy is an essential metric in the procurement process. When orders are incorrect, it can cause significant problems for businesses, including delayed shipments, additional costs, and even customer dissatisfaction. Additionally, inaccurate orders can lead to wasted time and manpower for businesses that need to correct errors. Therefore, it is critical to monitor order accuracy and identify any areas for improvement.

One of the most significant impacts of order accuracy on business efficiency is the effect on customer satisfaction. When orders are incorrect, customers may not receive the products they need when they need them, leading to frustration and dissatisfaction. This can lead to lost business and a damaged reputation for the company. On the other hand, when orders are accurate, customers are more likely to be satisfied with their experience and continue to do business with the company.

Another impact of order accuracy on business efficiency is the effect on the supply chain. When orders are inaccurate, it can cause delays in the procurement process, leading to longer lead times and slower delivery times. This can impact the entire supply chain, from the vendor to the end customer. Additionally, inaccurate orders can lead to excess inventory or stockouts, which can impact the bottom line of the business.

How to Calculate and Improve Order Accuracy

Businesses can calculate order accuracy by comparing the number of orders that were placed correctly with the total number of orders. This calculation can be done on a regular basis to identify any trends or issues that need to be addressed. Failure to identify issues within the procurement process can lead to ongoing mistakes and errors. Therefore, regular review and analysis of the procurement process are necessary to identify areas in which improvements can be made.

Improving order accuracy requires a multifaceted approach. One crucial aspect is training staff in best practices to ensure accuracy in every step of the procurement process, from order entry to vendor selection. Staff should be trained on how to input orders correctly, how to communicate with vendors effectively, and how to identify and resolve any issues that arise in the procurement process.

Another aspect of improving order accuracy is implementing technology solutions that can help automate and streamline the procurement process. For example, implementing an electronic procurement system can help reduce errors and improve accuracy by automating many of the manual processes involved in procurement.

In conclusion, order accuracy is a critical metric in the procurement process that can have a significant impact on business efficiency. By monitoring and improving order accuracy, businesses can improve customer satisfaction, reduce costs, and improve their bottom line.

Metric 2: Order Cycle Time

The Significance of Order Cycle Time in Supply Chain Management

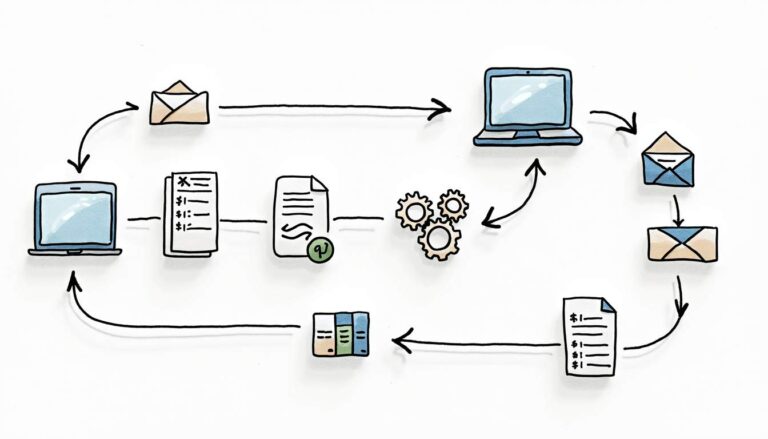

Order cycle time refers to the amount of time it takes to process an order from start to finish. This metric is crucial because it can impact the rest of the supply chain. The shorter the order cycle time, the more responsive and agile your business can be when it comes to meeting customer demand. Reducing the order cycle time can ultimately lead to increased customer satisfaction and revenue growth.

Strategies for Reducing Order Cycle Time

One strategy businesses can use to reduce order cycle time is to optimize their communication channels with suppliers. Close collaboration can help businesses make changes that improve overall efficiency and speed up the procurement process. Additionally, automation can streamline steps in the procurement process and minimize errors. Implementing tools like online ordering and automated inventory alerts can help reduce order cycle time while reducing the workload on staff.

Another strategy for reducing order cycle time is to implement a just-in-time (JIT) inventory system. JIT is a system where inventory is ordered and received just in time for production or sale. This system can help businesses reduce inventory carrying costs and minimize waste. By ordering inventory only when it is needed, businesses can reduce the amount of time it takes to process an order and improve overall efficiency.

It is also important for businesses to have a clear understanding of their customers’ needs and preferences. By analyzing customer data, businesses can identify trends and patterns in demand, allowing them to better anticipate their customers’ needs. This can help businesses reduce lead times and improve order cycle time.

Another way to reduce order cycle time is to improve the accuracy of order processing. This can be achieved by implementing quality control measures and ensuring that all orders are reviewed and verified before they are processed. By reducing errors in the order process, businesses can improve efficiency and reduce the amount of time it takes to process an order.

Finally, businesses can reduce order cycle time by improving their transportation and logistics processes. This can be achieved by optimizing delivery routes, using real-time tracking systems, and working with reliable logistics partners. By improving transportation and logistics, businesses can reduce lead times and improve overall efficiency.

Metric 3: Order Fill Rate

The Connection Between Order Fill Rate and Customer Satisfaction

A high order fill rate means that businesses can fill their customer’s orders accurately and on-time. A good order fill rate can be a significant driver of customer satisfaction and can lead to repeat business. However, failure to fill orders correctly can lead to customer dissatisfaction, which can ultimately damage a business’s reputation.

A high order fill rate is critical to the success of any business that sells products. Customers expect their orders to be filled accurately and on-time, and a business that cannot meet these expectations will quickly lose customers to competitors. In fact, studies have shown that customers are more likely to switch to a competitor after a poor delivery experience than for any other reason.

One of the main reasons that order fill rate is so important to customer satisfaction is because it is a measure of reliability. Customers want to know that they can count on a business to deliver their orders correctly and on-time, every time. If a business fails to meet this expectation, customers may begin to question the reliability of the business and may choose to take their business elsewhere.

Tips for Optimizing Order Fill Rate

Achieving a high order fill rate involves tracking and analyzing the inventory levels of products. Accurate inventory counts can help businesses better manage their stock, reducing the likelihood of stock-outs and backordering. Additionally, businesses can work with their suppliers to establish delivery and lead times that will ensure orders are filled correctly and on-time.

Another important factor in optimizing order fill rate is having a streamlined order fulfillment process. Businesses should have clear procedures in place for receiving, processing, and shipping orders. This can include using technology such as barcode scanners and automated inventory management systems to reduce errors and improve efficiency.

Finally, businesses should prioritize communication with their customers. Keeping customers informed about the status of their orders can help manage expectations and reduce the likelihood of dissatisfaction. This can include sending order confirmation emails, providing tracking information, and notifying customers of any delays or issues that may arise.

Metric 4: Order Cost Analysis

The Importance of Evaluating Order Costs

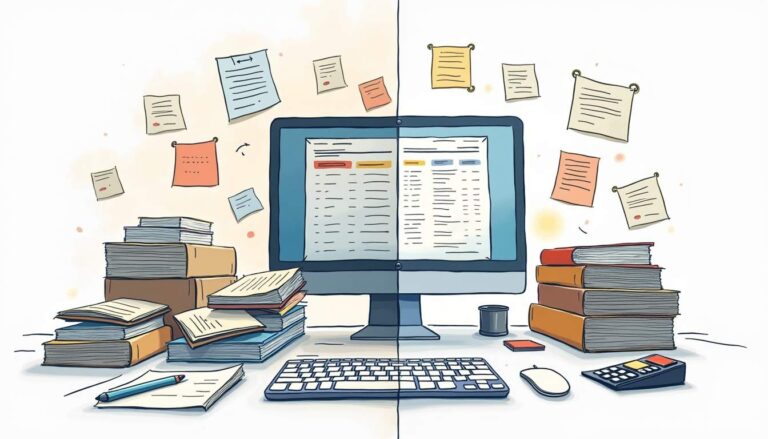

As businesses grow, the cost of procurement can grow, too. As costs increase, it becomes necessary to evaluate the expenses associated with the procurement process and identify areas of potential savings. Therefore, tracking order costs is an essential metric.

Techniques for Reducing Order Costs

One technique to reduce order costs is to negotiate prices with vendors. While this may seem obvious, businesses can benefit from regularly evaluating their procurement processes and vendors to ensure they are getting the best deals. Additionally, businesses can consolidate orders and ship through a single carrier to reduce shipping costs. Finally, tracking order costs can help businesses identify areas where they may be wasting money, such as over-ordering, which can cause an accumulation of inventory that may lead to spoilage or waste.

Conclusion

Tracking purchase order reports is essential for businesses of all sizes. These reports can provide critical insights that ultimately lead to cost savings, increased customer satisfaction, and more efficient business operations. By monitoring key metrics like order accuracy, order cycle time, order fill rate, and order costs, organizations can identify areas of improvement and optimize their procurement processes. Implementing best practices and using technology to automate processes can streamline operations and lead to ongoing improvements in the procurement process.

Is your team facing challenges with purchase order reports or related discrepancies? Check out how Bellwether can bring transparency to the process & help track every spend. Get a personalized demo today!