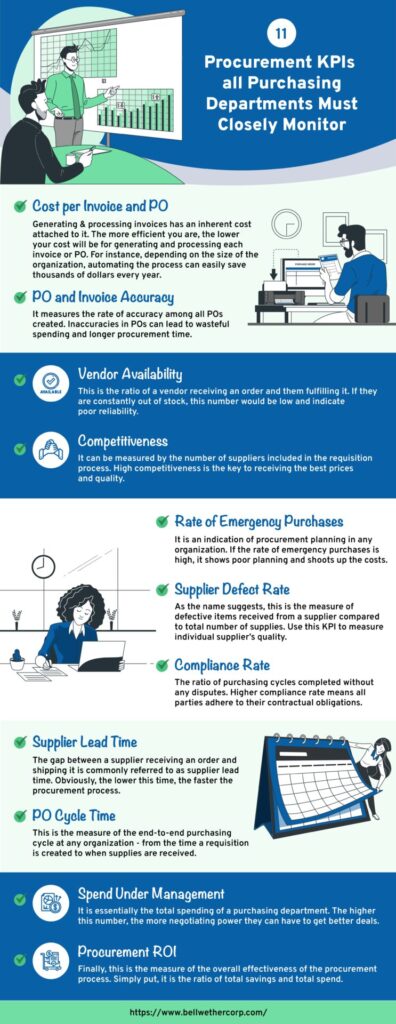

Responsible for roughly 40% of a company’s external spending, purchasing departments carry a lot of responsibilities and by extension, risks. Further, since much of their performance & productivity relies heavily on external factors like supply chain constraints, vendor availability etc., it is often tough to zero-in on the KPIs that most accurately & reliably reflect their functioning & performance.

That said, top procurement leaders have overtime, devised some KPIs to gauge into the various aspects of purchasing to get a better grasp of their their purchasing department’s functioning & efficiency. Here are the 11 key procurement KPIs along with their relevance that you too should constantly monitor:

1: Cost per invoice and PO

Generating & processing invoices has an inherent cost attached to it. The more efficient you are, the lower your cost will be for generating and processing each invoice or purchase order (PO). For instance, depending on the size of the organization, automating the process can easily save thousands of dollars every year.

2: PO and invoice accuracy

It measures the rate of accuracy among all POs created. Inaccuracies in POs can lead to wasteful spending and longer procurement time.

3: Rate of emergency purchases

It is an indication of procurement planning in any organization. If the rate of emergency purchases is high, it shows poor planning and shoots up the costs.

4: Supplier lead time

The gap between a supplier receiving an order and shipping it is commonly referred to as supplier lead time. Obviously, the lower this time, the faster the procurement process.

5: Vendor availability

This is the ratio of a vendor receiving an order and them fulfilling it. If they are constantly out of stock, this number would be low and indicate poor reliability.

6: Supplier defect rate

As the name suggests, this is the measure of defective items received from a supplier compared to total number of supplies. Use this KPI to measure individual supplier’s quality.

7: PO cycle time

This is the measure of the end-to-end purchasing cycle at any organization – from the time a requisition is created to when supplies are received.

8: Compliance rate

The ratio of purchasing cycles completed without any disputes. Higher compliance rate means all parties adhere to their contractual obligations.

9: Competitiveness

It can be measured by the number of suppliers included in the requisition process. High competitiveness is the key to receiving the best prices and quality.

10: Spend under management

It is essentially the total spending of a purchasing department. The higher this number, the more negotiating power they can have to get better deals.

11: Procurement ROI

Finally, this is the measure of the overall effectiveness of the procurement process. Simply put, it is the ratio of total savings and total spend.